LCD Knowledges

Innovative Backlight in TFT-LCD Field

Custom Backlight Solutions for TFT Displays

In the dynamic world of display technology, custom backlight solutions for Thin-Film Transistor (TFT) displays are crucial for enhancing display performance, longevity, and user experience.

Here’s an overview of the custom backlighting solutions offered by Metawistek Display.

Key Components of Custom Backlight Solutions

LED Configuration:

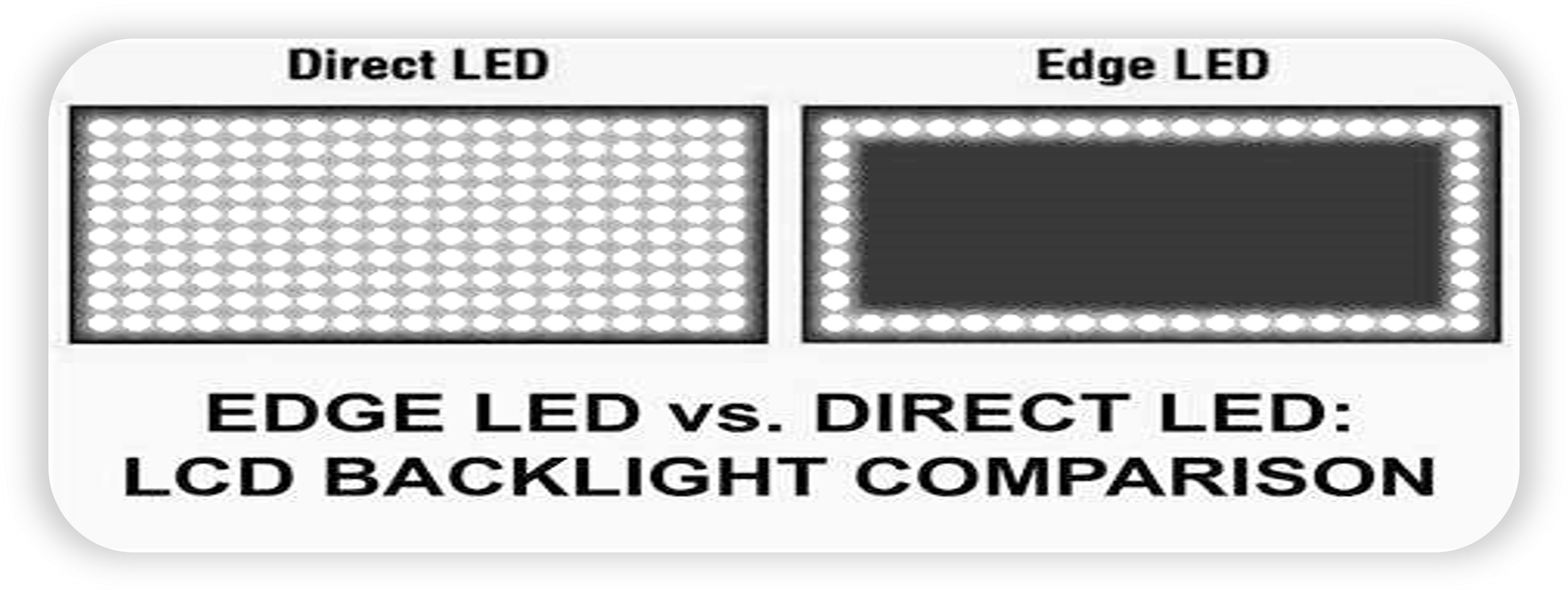

Edge-Lit Backlighting: Suitable for thin displays, LEDs are placed along the edges, and light is distributed across the screen using a light guide plate.

Direct-Lit Backlighting: LEDs are positioned directly behind the display, offering superior brightness and uniformity, ideal for larger displays.

Brightness and Dimming Control:

High-Brightness Solutions: Ensure readability in outdoor or high ambient light applications.

Dimming Capabilities: Include controls to adjust brightness based on ambient light, reducing power consumption and eye strain.

Color Temperature:

Customizing the color temperature enhances the display's color accuracy.

Cooler temperatures (5000-6500K) are used in medical displays, while warmer temperatures (3000-4000K) are preferred for consumer electronics.

PowerEfficiency:

Efficient backlighting systems reduce power consumption, crucial for battery-operated devices. Custom solutions optimize the number and type of LEDs and employ advanced drivers to manage power use effectively.

Mounting - Fixation Methods and Steps

To ensure a stable and reliable fixation of the LCD module to the metal plate, a combination of specific mounting methods and steps can be implemented. Here are some detailed descriptions of these methods:

a) Designing the Metal Plate and Positioning Pillars

Metal Plate Design: Design the metal plate with appropriate thickness and dimensions based on the size and shape of the LCD module. The plate should have good mechanical strength and thermal performance.

Positioning Pillars Design: Design a suitable number of positioning pillars on the metal plate, with heights and diameters precisely matching the mounting holes or edges of the LCD module.

b) Fixing the Positioning Pillars

Welding: Weld the positioning pillars to the metal plate, ensuring they are firmly attached and resistant to detachment or movement.

Screws: Use screws to fix the positioning pillars to the metal plate, providing reliable attachment through threaded connections.

Adhesive: For designs requiring weight reduction or avoiding complex metal processing, high-strength industrial adhesive can be used to bond the positioning pillars to the metal plate.

Adding Cushioning Materials: Add cushioning materials (such as silicone pads or foam pads) at the contact points between the LCD module and the metal plate or positioning pillars to reduce vibration and impact, preventing damage during transport and use.

Anti-Static Measures: Take anti-static measures during installation, such as wearing anti-static gloves and using anti-static mats on workbenches, to prevent static electricity from damaging the LCD module.

Requirement Analysis:

Detailed analysis of application requirements, including environmental conditions, desired brightness levels, power constraints, and color accuracy needs.

Prototyping and Testing:

Developing prototypes to test different configurations and materials, followed by rigorous testing to ensure performance and durability criteria are met.

Optimization:

Refining the backlight design based on testing results to balance performance with cost and manufacturability.

Integration and Production:

Final integration of the custom backlight into the TFT display, followed by full-scale production with continuous quality checks.

Benefits of Custom Backlight Solutions

Enhanced Performance: Tailored solutions ensure optimal display performance, offering better visibility and user experience.

Energy Efficiency: Customization leads to significant power savings, extending the battery life of portable devices.

Durability: Designed to withstand specific environmental stresses, enhancing display durability.

Brand Differentiation: Unique backlight characteristics can provide a competitive edge.

Importance of Custom Backlight Solutions

Backlighting is essential for ensuring visibility and readability in various lighting conditions. Custom backlight solutions optimize brightness, uniformity, color temperature, and power efficiency tailored to specific use cases, ensuring displays perform optimally in their intended environments.

Custom backlight solutions for TFT displays are essential for meeting diverse modern display applications. By focusing on key components like LED configuration, brightness control, color temperature, and power efficiency, manufacturers can create displays that excel in their intended environments. Partnering with experienced providers like Metawistek Display ensures the final product meets and exceeds performance expectations.

For more detailed information, visit Metawistek Display

相关新闻

导航栏目

新闻中心

联系我们

联系人:Aaron Liu

手机:+86-189 6727 9142

电话:+86-189 6727 9142

邮箱:metawistek@rgblcd.com